In the summer compost breaks down pretty quick and a 5 gallon bucket lasted most of the summer. Then it started getting cold and I just had to come up with a better solution. First stop was craigslist.org, 2 steel 55 gallon drums for $30.

I cut a hole in the top about 12" x 12" and then cut out a larger piece from scrap sheet metal that was in my garage. Added some hinges and a latch that were from old cabinets that I cleaned up years ago and put some old paint on for a finishing touch. Sometimes it pays to never throw anything away. Also drilled some holes in the sides to let gases escape. I've a plan for pvc pipe with holes drilled in it to help get air to the compost, it's still a half baked plan though.

Mixing compost so that air gets in speeds the breakdown process and prevents anaerobic bacteria from creating methane gas. The next step is a frame to hold the drum on a pivot to make turning it easy. A few years ago I made a trebuchet and it was fun to play with but time to move on so the frame from the trebuchet will now be the frame for a compost turner.

The base will need new cross beams since the drum is much wider than the throwing arm was. Since trebuchets were medieval siege weapons I went with the old school carpentry and didn't use any glue or nails. That means that making new cross beams takes time and needs warmer weather. It is a simple enough process though. Drill two holes that are the width and distance of the tenon, as seen in the picture, then chisel out the middle. Drill a hole for the peg and then insert peg.

I saw a number of compost turners with plastic drums on the internet and it just doesn't seem like the plastic would hold up. In fact it doesn't seem like the steel will hold up so I reinforced the hole with a 3/4" washer that fits the 1/2" conduit pipe with a little to spare, I would feel better if the washer was welded on. 1/2" conduit seems like it is just barely strong enough, I wanted to start with something thicker but then I would of had to fabricate a reinforcement and it was cold in the garage. Why haven't I spent more time putting up the insulation and drywall in the garage? After putting up a 4x8 sheet of 1/2" drywall by myself on a 10' ceiling I decided to wait till warmer days and recruit some help. Anyway, the base will have wheels on one end to help move around the yard but also to aid in swapping out the drum. Once it is done the non-wheeled end can be upended to place the drum on the ground top up. Then the axle can be slid out and the frame wheeled over to a new drum where the axle gets put back in. More on that later.

The other project is earthen plaster. My yard is mostly clay and clay is a main ingredient in earth plaster but not all clays make good plaster material. There are some easy and basic tests that can be done to find out what properties a clay has.

This first test is to put some dirt in a glass jar with some water and shake it up. Then set the jar down for 24-48 hours and take a look. The sediment in the jar will give a rough idea of how much sand, clay and silt is in the dirt. The bottom will be sand, then silt and finally clay. This is almost pure clay. Sand will have to be added to make an earth plaster.

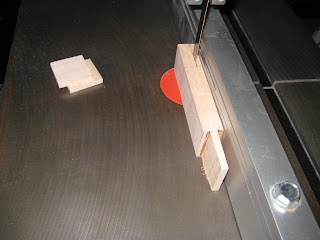

The next test is to make a box to test shrinkage. Some clay will shrink a lot when it dries and some hardly at all. My area is know for it's bentonite clay which expands and shrinks considerably with moisture and is a poor clay for plaster. This was some scrap maple from the kitchen cabinets and a couple of coats of varnish. There is currently mud drying out in it, since it is so cold it might be a few days before I know what kind of clay I have. As long as the clay shrinks less than 15% it should work for plaster. The test box is 20 centimeters long which comes out to about 5/8" maximum shrinkage.

Plaster recipes have anywhere between 2 parts sand to 1 part clay to 4 parts sand. Really it depends on the clay and the quality of the sand, river and beach sand should be avoided. To find the right mixture start on the low end and keep adding sand, take notes. Two things should happen when the right mixture is found. One is if you take some of the mud mix and roll it into a cigar shape, 1/2"ish round by 5"ish long and slowly push it off of your hand. If it crumbles falls apart add more clay. If it breaks about halfway you have a good mixture. If it doesn't break and just curls as it is pushed off of your hand then add more sand. Another test is to roll a half a handful into a ball and let it dry. If it easily disintegrates then add clay. If it takes pressure to break and crumble it is probably good. If you can't break it with your fingers then the mix probably needs more sand. It should also be mentioned that less water is better, add just enough to make the material workable.

The goal is to build a green house in the back yard out of earth plaster and then coat the outside in lime plaster. Really it depends on how long we will stay here though. It is fun to play with in the mean time though.